provisions for designing reinforcing bars for development, and for designing an anchorage into a concrete member. CSA A23.3:19 Chapter 12 contains reinforcing bar development provisions. CSA A23.3:19 Annex D contains provisions that can be used to design cast-in anchor bolts and post-installed anchors, including post-installed reinforcing bars, as part of a concrete anchorage. Post-installed reinforcing bars can also be designed for development using, for example, CSA A23.3:19 Chapter 12 provisions if they have been evaluated as part of an overall adhesive anchor system to establish equivalency with cast-in reinforcing bars.

CSA A23.3 Chapter 12 provisions are predicated on bar installation with small concrete cover such that the bar must be embedded deep enough to preclude splitting failure in order to be “developed”, i.e. reach its yield strength (fy MPa). The embedment required to yield a bar is a calculated value that is referred to as the “development length” of the bar. Chapter 12 provisions conservatively assume splitting failure will occur even when bars are installed at a large distance from a fixed concrete edge; however, when bars are installed at a large distance from a fixed concrete edge, pullout failure or concrete breakout failure is more likely to occur in lieu of splitting failure. Since Annex D provisions consider pullout and concrete breakout as possible failure modes, reinforcing bars installed at a large distance from a fixed edge might be more efficiently designed for development using these provisions in lieu of Chapter 12 provisions. This paper will discuss how post-installed reinforcing bars can be designed for tension development using the anchoring-to-concrete provisions in CSA A23.3:19 Annex D in lieu of the development provisions in CSA A23.3:19 Chapter 12*.

General Design Procedure

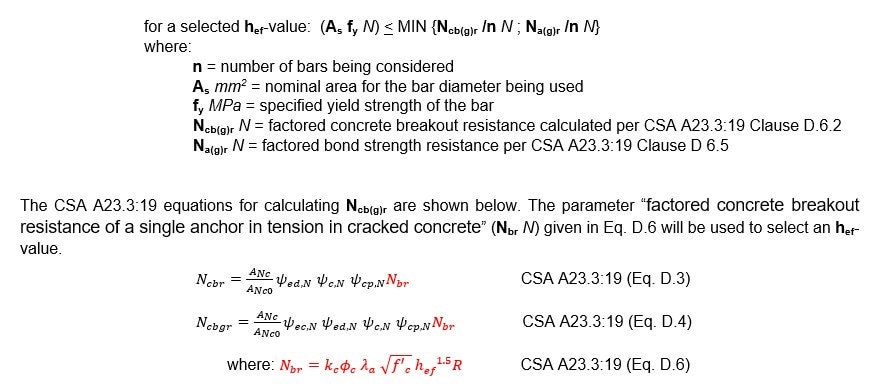

CSA A23.3:19 Annex D is titled Anchorage. The provisions in Annex D are used to design cast-in anchors (e.g. headed studs and headed bolts), post-installed mechanical anchors, and post-installed adhesive anchor systems. An adhesive anchor system consists of the adhesive product, the anchor element, and the installation procedure. Anchor elements used in an adhesive anchor system include threaded rods, reinforcing bars, internally threaded inserts and proprietary elements. Annex D provisions consider possible anchor failure modes. When designing a post-installed reinforcing bar for tension development using anchoring-to-concrete provisions, bar yielding must control the design in lieu of concrete breakout failure in tension and bond failure in tension. Therefore, the embedment depth (hef mm) of the bar must be sufficient to both yield the bar and to preclude concrete breakout failure in tension and bond failure in tension. This provision can be considered satisfied if the factored concrete breakout resistance in tension (Ncb(g)r /n N) and the factored bond resistance in tension (Na(g)r /n N) per individual bar including the effects of grouping are greater than the nominal steel strength in tension (Asfy N) for the embedment depth that has been selected and the number of bars (n) being considered. This concept is summarized as follows:

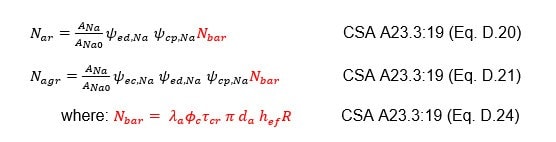

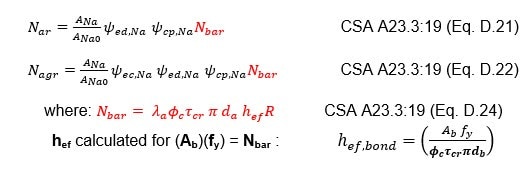

The CSA A23.3:19 equations for calculating Na(g)r are shown below. The parameter “factored bond resistance of a single adhesive anchor in tension in cracked concrete” (Nbar N) given in Eq. D.23 will also be used to select an hef-value.

Consider a group of post-installed bars being designed for development in tension. Let the nominal steel strength of a single bar be defined as (As)(fy). If the factored concrete breakout resistance calculated of each bar (Ncb(g)r/n), and the factored bond resistance calculated of each bar (Na(g)r/n) are both greater than (As)(fy), where “n” corresponds to the number of bars; the yield strength of the bars controls the design. By equating (Nsar N) for a single bar, i.e. Nsar = (As)(fy), to (a) Nbr calculated per Eq. (D.6) and (b) Nbar calculated per Eq. (D.24), and solving for hef; an embedment depth corresponding to yielding the bar can be determined. The greater of the hef-values that have been calculated can then be used to calculate (Ncb(g)r N) and (Na(g)r N) for the number of bars (n) being developed in tension. If Ncb(g)r/n and Na(g)r/n calculated with this hef-value are both greater than (As)(fy), the embedment (hef) can be considered sufficient to yield the bars yet preclude concrete breakout failure and bond failure. If either Ncb(g)r/n or Na(g)r/n calculated with the hef-value are less than (As)(fy), the embedment (hef) is not sufficient to preclude concrete breakout failure and bond failure. A different embedment, and/or a new bar diameter and/or steel grade must be selected; and the design procedure repeated. The next section will explain the design procedure in detail.

Post-Installed Reinforcing Bars Designed to Yield Using Anchoring-to-Concrete Provisions

Post-installed reinforcing bars can be designed per CSA A23.3:19 provisions if the adhesive product used to install the bars has been evaluated per a recognized testing program. Hilti adhesive anchor systems are evaluated per the International Code Council Evaluation Service (ICC-ES) acceptance criteria titled Acceptance Criteria for Post-Installed Adhesive Anchors in Concrete Elements (AC308) to (a) demonstrate compliance “in the opinion of ICC-ES” with the National Building Code of Canada (NBC), and (b) obtain data for designing the adhesive anchor system using CSA A23.3 provisions. Adhesive products that satisfy the provisions of ACI 355.4 by meeting the requirements of the test program outlined in AC308 Table 3.2 can be used to post-install reinforcing bars that are designed per CSA A23.3 anchoring-to-concrete provisions. Adhesive products that satisfy the provisions of the test program outlined in AC308 Table 3.8 can possibly be used to post-install reinforcing bars that are designed using CSA A23.3 development and splice theory*.

Per Table 3.2 criteria, the embedment depth (hef mm) for a post-installed reinforcing bar designed with CSA A23.3 anchoring-to-concrete provisions (i.e. CSA A23.3:19 Annex D provisions) is limited to a maximum depth of 20 bar diameters: hef < 20(da mm). Per Table 3.8 criteria, the maximum embedment depth for a post-installed reinforcing bar designed with CSA A23.3 development provisions (e.g. CSA A23.3:19 Chapter 12) is 60 bar diameters: hef < 60da*. Since Hilti adhesive products that satisfy the test program in AC308 Table 3.2 can be designed with anchoring-to-concrete provisions, and products that satisfy the test program in AC308 Table 3.8 can be designed for development (i.e. yielding); Hilti adhesive products that satisfy the test programs in AC308 Table 3.2 and Table 3.8 can be assumed to be acceptable (with possible modifications) for development (yield) design using anchoring-to-concrete provisions at embedment depths up to 60da*.

CSA A23.3 provisions for calculating ld are concerned with embedding a bar deep enough to “develop” the yield strength without splitting failure occurring. “Splitting failure” refers to cracking and splitting in the concrete around bars in tension. Designing post-installed reinforcing bars for yield using anchoring-to-concrete provisions considers the possibility of concrete breakout failure or bond failure in lieu of splitting failure by considering embedment depth, spacing between bars, any fixed edge conditions, and product-specific parameters such as the “characteristic bond stress” of the adhesive (tk,cr MPa).

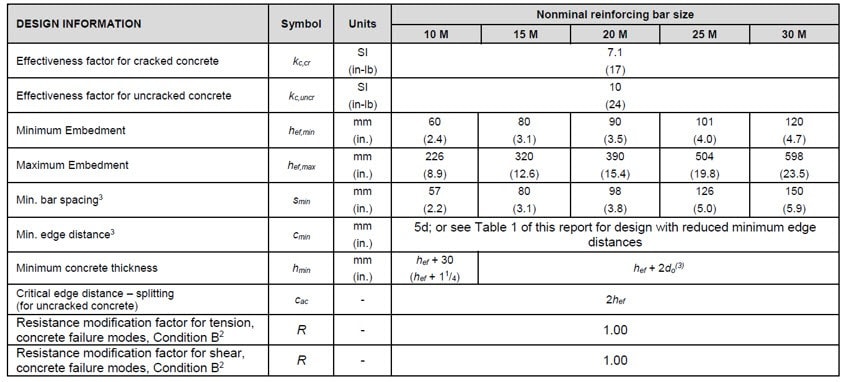

Design data for adhesive anchor systems evaluated per the test programs in AC308 is given in an ICC-ES evaluation report (ESR) or evaluation listing for Canada (ELC). This data is product-specific and can be used to design the adhesive system with CSA A23.3 provisions. With respect to post-installed reinforcing bars, data for minimum geometry requirements, bar spacing, edge distance and concrete thickness derived from the test program outlined in AC308 Table 3.2 will be given in tables within the ESR/ELC. This data is relevant when designing bars with CSA A23.3 anchoring-to-concrete provisions. Data for bar spacing and concrete cover derived from the test program outlined in AC308 Table 3.8 will only be given in the ESR. CSA A23.3 remains silent on the prequalification of anchoring products for use with the development and splicing provisions of Chapter 12. Although not provided in ELCs, this data demonstrates an adhesive anchor system’s equivalency to the cast-in rebar counterpart and is relevant when designing bars with CSA A23.3 development provisions*. These parameters differ from the parameters for anchoring-to-concrete provisions. Therefore, when designing post-installed reinforcing bars for development using anchoring-to-concrete provisions, always follow the geometry parameters for anchoring-to-concrete provisions that are given in the design tables.

The table below shows minimum geometry parameters given in ELC-3187 for anchoring-to-concrete provisions.

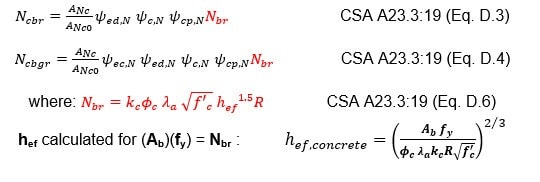

Determine hef for Yield

The nominal steel strength in tension of a reinforcing bar (Nsa N) is calculated using the cross-sectional area of the bar (Abar mm2) and the specified yield strength (fy MPa) of the bar: (Nsa N) = (Abar mm2)(fy MPa).

Equating (Abar mm2)(fy MPa) for a single bar to the factored concrete breakout resistance of a single anchor in tension in cracked concrete (Nbr N) and the factored bond resistance of a single adhesive anchor in tension in cracked concrete (Nbar N), and solving for hef mm; a trial embedment depth to yield the bar can be determined. As shown on pages 1 and 2, Nbr is used to calculate the factored concrete breakout resistance in tension (Ncb(g)r N) and Nbar is used to calculate the factored bond resistance in tension (Na(g)r N). Therefore, the hef-value that is calculated by equating (Abar)(fy) to Nbr and to Nbar will correspond to an embedment depth required to yield the bar with respect to concrete breakout and bond failure, respectively.

The larger value calculated for hef controls such that MAX {hef,concrete : hef,bond} is used to calculate Ncb(g)r and Na(g)r.

The projected concrete failure area of a single anchor or group of anchors (ANc mm2) with respect to calculation of Ncb(g)r is dependent on the concrete interface geometry and bar layout within the interface. Projected distances from bars relevant to fixed edge conditions and bar spacing will be considered for calculation of ANc. Per CSA A23.3:19 Clause D.6.2.1, the maximum assumed projected distance from a bar with respect to concrete breakout in tension is limited to a value of 1.5hef. The maximum assumed spacing between two bars is limited to a value of 3hef. Minimum permissible edge distance values (cmin mm) and spacing values (smin mm) are given in the adhesive product ESR/ELC. Therefore, the influence from any fixed edges, MIN {edge distance : 1.5hef}, as well as the influence from bar spacing, MIN {spacing : 3hef}, must be considered when calculating ANc.

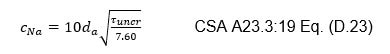

Calculations for nominal bond strength in tension (Na(g)r) are predicated on the projected distance parameter cNa in, which is defined as follows:

The projected influence area of an adhesive anchor or group of adhesive anchors (ANa mm2) with respect to calculation of Na(g)r is also dependent on the concrete interface geometry and bar layout within the interface. Therefore, projected distances from bars relevant to fixed edge conditions and bar spacing are likewise utilized to calculate ANa. Per CSA A23.3:19 Clause D.6.5.1, the maximum assumed edge distance from a bar with respect to bond failure is limited to a value of cNa. The maximum assumed spacing between two bars is limited to a value of 2cNa. Therefore, the influence from any fixed edges, MIN {edge distance : cNa }, as well as the influence from bar spacing, MIN {spacing : 2cNa}, must be considered when calculating ANa.

Check MIN {Ncb(g)r/n : Na(g)r/n } > (Abar)(fy)

Once the factored concrete breakout resistance (Ncb(g)r N) and factored bond resistance (Na(g)r N) have been calculated with MAX {hef,concrete : hef,bond}, the resistance offered from each bar must be checked against the nominal steel strength in tension (Abar)(fy). If Ncb(g)r/n and Na(gr)/n calculated with MAX {hef,concrete : hef,bond} are greater than or equal to (Abar)(fy) for the number of bars being considered, the embedment depth can be considered sufficient to yield the bars, yet preclude concrete breakout failure in tension and bond failure in tension. If Ncb(g)r/n and Na(g)r/n calculated with this hef-value are less than (Abar)(fy), an alternative design, such as tension development determined per CSA A23.3 Chapter 12, can be considered.

Summary

This paper discussed how post-installed reinforcing bars can be designed for tension development using the anchoring-to-concrete provisions in CSA A23.3:19 Annex D in lieu of the development provisions in CSA A23.3:19 Chapter 12*.

This design premise is feasible when concrete breakout failure and bond failure preclude splitting failure.

*The evaluation of a post-installed reinforcing bar system as an alternative to cast-in-place reinforcing bars using the development length provisions of ACI 318 and CSA A23.3 is outside of the scope of ACI 355.4. The suitability of this application is evaluated under ICC-ES Acceptance Criteria AC308, Table 3.8.