Frequently Asked Questions for Hilti's AT System for use with Hilti Anchor Channel

TYPICAL AT SYSTEM QUESTIONS

Q1) IS IT PERMISSABLE TO SET T-BOLTS WITH AN IMPACT WRENCH?

The general answer is no: common impact wrenches do not have any controls on the applied torque and therefore bring a high risk of under-torquing (the system has not the torque to work properly) or over-torquing (the fastening system or the base material get damaged).

Things are different in case of the setting of the Hilti Anchor Channels (and many other fastening systems) with the AT System. Since the system has been studied for this purpose, it is not only permitted by Hilti but also recognized in the relevant product approval (e.i., ICC ESR).

Q2) IS THE AT MODULE SYSTEM COVERED BY ICC ESR-3520?

Yes, the AT Module System is a model code compliant t-bolt installation method.

The Hilti’s Anchor Channel System is covered by the International Code Council Evaluation Service (ICC-ES) Evaluation Report ESR-3520 with the SIW 6AT-A22 impact wrench and SI-AT-A22 module as setting method in addition to the traditional torque wrench.

Having the AT system covered by an ICC-ESR means that the installation with the AT System, had to undergo to a severe examination performed by external testing institutes. The ICC-ESR was only released when all the AC232 requirements were successfully met. Multiple rigorous test series are necessary to verify that in several conditions, the required pre-tension force is achieved. In addition, the base material and the fastening elements must not be damaged.

The AT Module System approval process mandates the same rigorous testing conditions as t-bolts installed via impact wrench.

Q3) CAN THE HILTI T-BOLTS BE SET WITH ANY IMPACT WRENCH?

No. In fact, the Hilti t-bolts can be set only if the SIW 6AT-A22 impact wrench is utilized with the AT Module (SI-AT-A22).

Q4) WHAT IS AN IMPACT WRENCH?

An impact wrench is a power tool designed to deliver high torque output with minimal exertion by the user. This is achieved by storing the power output of the high efficiency brushless motor in a rotating mass. This energy is then suddenly transferred to the output shaft resulting in regular hits. The working principle is similar to that of a pneumatic hammer in that the energy is stored in the hammering mass which hits the drill bit. Impact wrenches are widely used in several applications where a high torque output is required and the sensitivity to the torque is relatively low (1).

Q5) HOW DOES THE AT MODULE KNOW WHEN THE RIGHT INSTALLATION TORQUE HAS BEEN APPLIED?

Installation torque is an indirect means to achieving the right pretension. Installation instructions for anchors typically require a specific installation torque. The torque is used to turn a nut onto the fastener to stretch it, thus creating this pre-load or pretension.

The best way to picture this pretension is by over-torquing a bolt. Once a bolt experiences a relatively high installation torque, it will stretch then eventually ruptures (fails). The pre-tension force that ruptures the bolt is the result of the applied installation torque.

The AT System is designed instead to apply a consistent, appropriate pre-tension force (not installation torque). A consistent pretension by means of the AT System leads to proper setting of the embed t-bolts assuming all other steps are properly followed per the Instructions for Use. This is the reason why ICC ESR-3520 allow the utilization of the AT system for the setting of the HBC T-bolts.

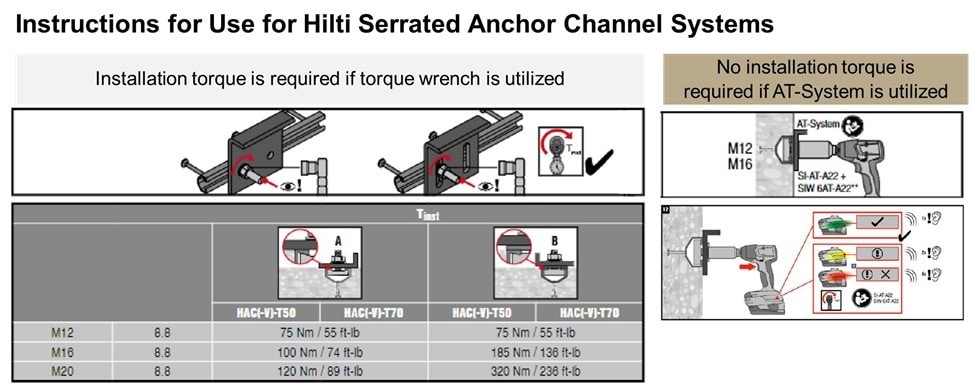

Figure 1 – T-bolt Installation requirements for different setting methods

The output of an impact wrench, when hammering, is a very short impact force. The actual effective torque is difficult to measure outside of a laboratory. The AT System, thanks to the electronic motor speed control several sensors built in the tool and product specific algorithms, is able to more safely meet the pretension requirements of the fastener and fulfill the demand of AC232.

Q6) HOW DOES THE USER KNOW WHEN THE AT SYSTEM HAS INSTALLED THE T-BOLT CORRECTLY?

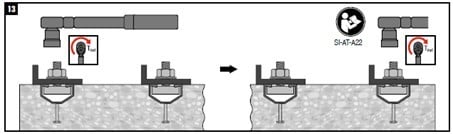

The AT System may display a green, yellow, or red light after the t-bolt is installed. Figure 2 illustrates the meaning of each light color. A green light will appear if the t-bolt was pretensioned properly. The AT System Outputs shown in Figure 2 are only applicable to HAC System. In addition, a “beeping” sound will be made by the AT System once the t-bolt is set.

Figure 2 – AT Module Outputs

Q7) WHAT T-BOLTS CAN BE INSTALLED WITH THE HILTI’S SIW 6AT-A22 CORDLESS IMPACT WRENCH WITH THE SMART HILTI ADAPTIVE TORQUE MODULE SI-AT-A22?

Figure 3 – HAC System portfolio covered by SIW 6AT-A22 Cordless Impact Wrench with the smart Hilti Adaptive Torque Module SI-AT-A22

Q8) HOW LONG DOES IT TAKE ON AVERAGE TO SET A T-BOLT WITH THE AT SYSTEM?

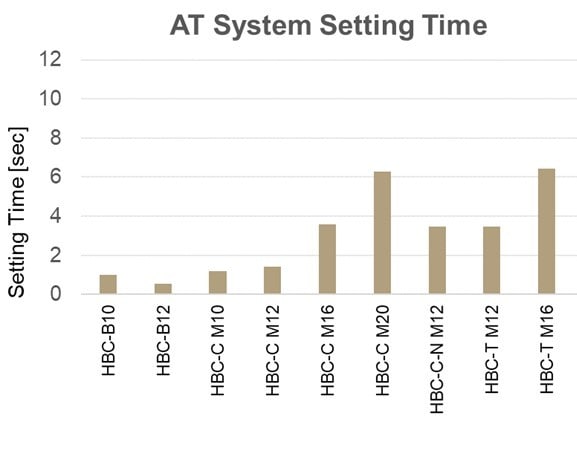

Figure 4 – Setting time in seconds of Hilti HAC T-bolts with SIW 6AT-A22 Cordless Impact Wrench with the smart Hilti Adaptive Torque Module SI-AT-A22

Q9) IF THE T-BOLTS ARE INSTALLED WITH THE AT SYSTEM, CAN YOU SPOT CHECK WITH A TORQUE WRENCH?

Yes. Spot checks with torque wrench are required as part of the installation requirements and best practices.

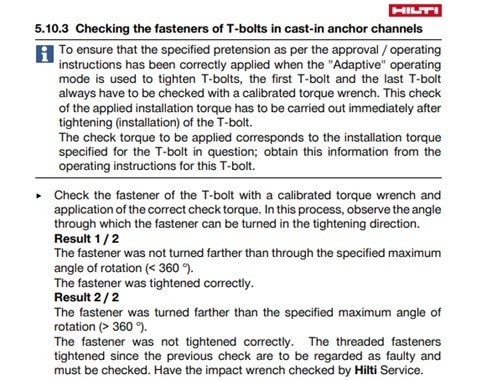

As specified in the manual, when spot checking the adequacy of fasteners installed with the AT module, it is important to make sure that the rotation of the nut is smaller than 360°. If this value is exceeded, please contact Hilti immediately.

Figure 5 – Checking the fasteners of T-bolts in cast-in anchor channels

If a torque wrench is utilized to cross check the AT System, the torque value may exceed the published torque values; that is acceptable. The AT System has been programmed to account for different site-conditions such as the anchor channel been recessed into the slab. Such site tolerances may lead to a variance on the actual torque in the system, which may be observed when checking the fastener with a torque wrench. Even though the torque with the AT System can be higher, the pretension will be within the permitted range, helping to ensure the fastener and base material are not damaged.

When spot checking the adequacy of fasteners installed with the AT module, it is important to make sure that the installation torque is at least equal to the one given in the approval and on the instruction for use of the relative T-bolt. If it is less, please contact Hilti immediately.

Q10) DOES IT MAKE SENSE TO CHECK THE INSTALLATION TORQUE WITH A TORQUE WRENCH?

As explained above, the pretension is the only important parameter for the functioning of a t-bolt. The rotation of the nut when installing with an impact wrench proceeds stepwise with the impacts of the nuts. With a torque wrench, the rotation proceeds more or less steadily. Static and dynamic friction may differ significatively. The static and dynamic friction is different. If a torque wrench is utilized to “measure” the installation torque of a fastener installed with the AT System, the value achieved when the nut starts to turn may exceed the one provided in the Instructions for Use for Torque Wrench Installation. The rotation of the nut is the only parameter that can be checked. As specified in the AT-Module user manual, during a check with the torque wrench, it can be only verified that the angle of rotation is smaller than the prescribed value. It is not a problem; in case the nut does not rotate at all.

Q11) HOW DOES THE AT MODULE KNOW WHEN TO STOP?

Thanks to the electronic motor speed control, several sensors built in the tool and product specific algorithms, Hilti’s SIW 6AT-A22 Cordless Impact Wrench with the smart Hilti Adaptive Torque Module SI-AT-A22 is able to safely meet the pretension requirements of the fastener and fulfill the demand of modern regulations such as AC232.

Q12) IS SETTING OF THE FASTENERS “THAT” IMPORTANT?

Yes. Having the right pre-tension force on the fasteners is needed to help ensure it performs as intended.

A lower pre-tension force or lower installation force may compromise the performance of the fastener making it structurally unsafe. For instance, a loosen t-bolt may not allow adequate engagement of the t-bolt and channel lip, leading to reduced slip resistances.

A higher pre-tension force may damage the fastener and/or base material which can compromise its performance. The main difference between an impact wrench and the AT System is the impact wrench is uncontrolled and variable during running. As stated above the AT system regulates all of the variables to help ensure proper pretensioning. See previous question for explanation why higher installation torques are ok with the AT System.

Q13) CAN THE AT SYSTEM DOCUMENT AND GENERATE A REPORT OF EACH INSTALLATION DATA POINT?

Yes, the AT Module can be connected to the computer via USB. With the Assistance of Hilti AT Documentation Software, the report can easily be generated.

Figure 6 – AT Module connected to PC

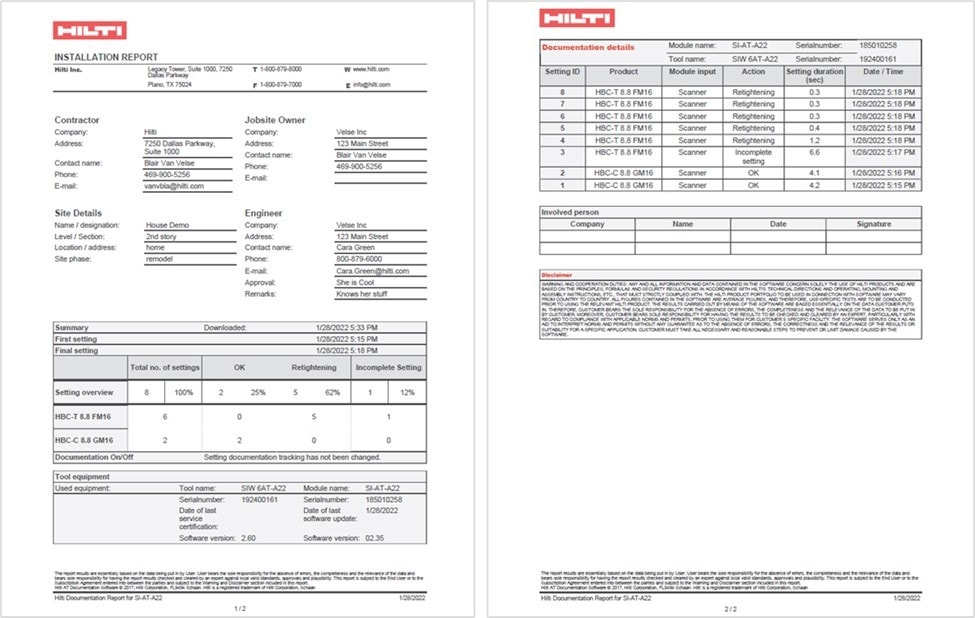

Q14) WHAT INFORMATION IS PROVIDED IN THE AT SYSTEM REPORT?

The report provides the following information:

· Project information such as contractor information, site details, jobsite owner, and engineer.

· Summary of data points collected with overall installation results

· Details each data point with t-bolt type, module input, action, setting duration in secs, date and time

Figure 7 – AT Module Report

Q15) WHAT IS THE MAXIMUM NUMBER OF POINTS THAT CAN BE STORED IN THE AT SYSTEM?

10,000 data points can be stored.

Q16) WHAT ARE THE DIMENSIONS OF THE SIW 6AT-A22 CORDLESS IMPACT WRENCH?

See Figure 10 for dimensions.

Figure 8 – Dimensions of Hilti’s SIW 6AT-A22 Cordless Impact Wrench

References

1) 2 "Side by side: Cordless impact wrenches". 25 December 2007. Archived from the original on 25 December 2007.